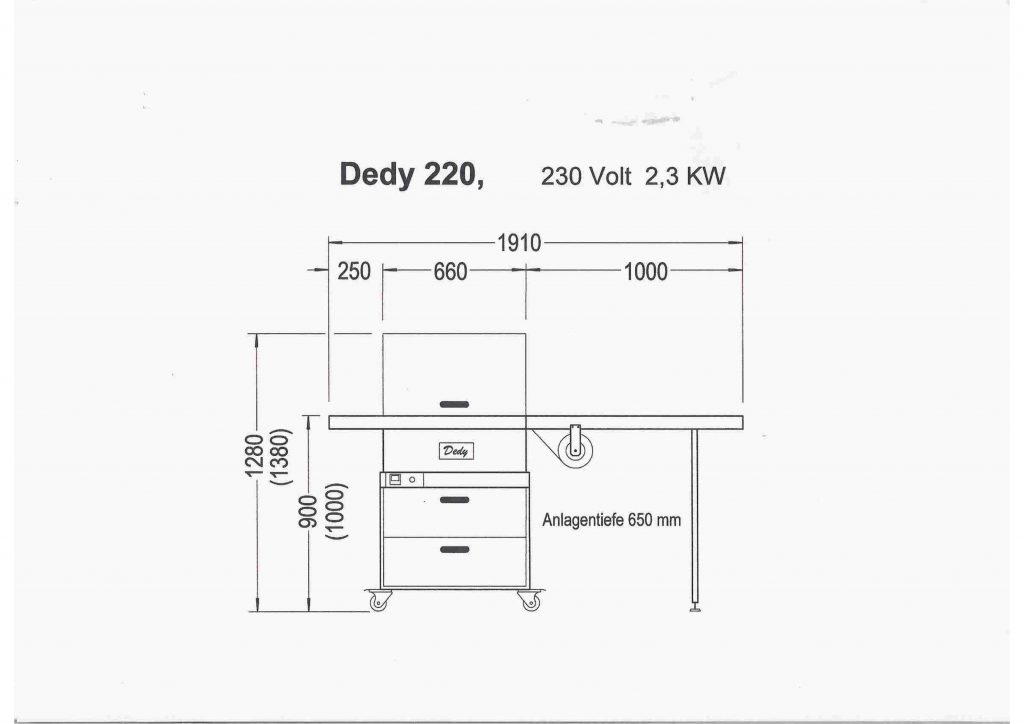

Our smallest model the 120mm enrobing machine has a capacity of 15 kg chocolate and will be delivered as table model. The standard model is equipped with a removable 1 meter take-off-table to set up the enrobed goods on paper and it is equipped with a pouring device for filling chocolate into chocolate moulds

Pastries of all kinds and small cakes up to a height of approximately 5 cm, as well as cream cheese and for example dates can be enrobed with chocolate coating, fudge, sugar icing or glaze. The machine normally runs at a belt speed between 0.5 and 2 m per minute, the belt speed is infinitely variable. The so-called evener cylinder which is mounted at the end of the belt prevents the coating from producing threads. All parts of the machine are designed to be very easy to clean, extremely robust and user friendly. Total enrobing, bottom enrobing, combined bottom, side and partial enrobing are possible. The exact chocolate temperature is controlled via an extremely sensitive digital thermostat with a one-tenth centigrade scale. Heating is achieved via a built-in fully electronic air circulation system. Two thermostats allow for a standby mode and a production mode. The belt, the chocolate wheel, and the chocolate tank are easily replaceable.

The entire machine is made out of stainless steel.

Power supply: 1 ph; 230 V, 50 – 60Hz.